VATA REFRIGERANT AIR DRYER

Introduction Company Profile

First Air Solution Co., Ltd. We are designs and develops the Thai brand air dryer "VATA AIR COMPRESSOR" by a team Thai engineers with over 20 years of experience in air compressors. The product development under modern concept that i: easy to use and maintain. Expert with sales and after sales services. Our products are the right for all types of industrial pla

Under the vision "Moving together" We focus to develop products and human resources to be ready to take care our customers. For all alliance growth in sustainable ways.

AIR DRYER

series freeze dryer adopts advanced technology, high quality components, according to ISO quality standards for compressed air (ISO8573.1) Manufactured high performance drying equipment, university, reliable, environmentally friendly, energy saving, and intuitive.

Performance characteristics of freeze dryer

» Special rear cooler and pre-cooler can directly access high temperature compressed air 70 degree C.

» Super-strong design centrifugal and collector dual water separators with wate rseparation efficiencyhigher than 99%

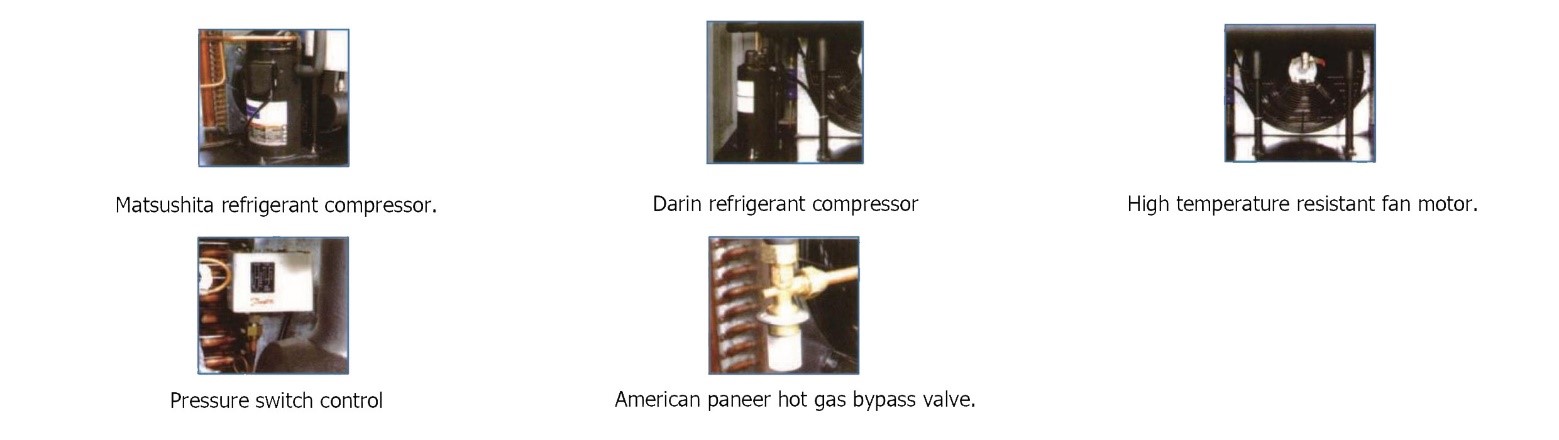

» It adopts world famous spare parts with excellent quality and long service life.

» Easy to use, no consumables, automatic drainage, low operating cost, reliable and continuous operation

Door protection, energy saving and high efficiency freeze dryer Technology

Cyclone gas-liquid separator

The cold compressed air, condensate oil and condensate water are formed by mixing compressed gas after post-cooling, pre-cooling and heat absorption of refrigeration system through a cyclone gas-liquid separator. The cyclone produces strong centrifugal force to completely separate air, condensate oil and condensate water. The condensate oil water is discharged through an automatic sewage drainage system, except for water efficiency which is higher than 99.9% For other condensate oil water natural discharge or interception discharge, the output air drying efficiency is 50% higher, and its water removal capacity almost keeps constant under the condition of low air system pressure and unstable air supply pressure.

Rabbit Maintenance Sewerage System

YK Maintenance-free sewage drainage system is specially and carefully designed. Condensate oil and water can be quickly deduced from gas-liquid separation by diversion pipeline to prevent water from flowing back with gas. Condensate impurities in large-volume sewage storage space are designed to avoid regular cleaner and trouble. 200 mesh stainless steel filter net is equipped to effectively prevent blockage of electronic drainage device, and high-quality electronic drainage valve is matched. The sewage system can efficiently and automatically remove the separated condensate oil under the condition of long-term operation. Automate sewage disposal without waiting, pre-planning, eliminating the advantages of backward consideration.

Import original Accessories

|

Type of dryer |

FA-10 |

FA-15 |

FA-20 |

FA-30 |

FA-50 |

FA-75 |

FA-100 |

FA-150 |

FA-200 |

|

|

Applicable to air compressor (KW) |

7.5 |

11 |

15 |

22 |

37 |

56 |

75 |

110 |

150 |

|

|

Air handling capacity m3/min |

1.5 |

2 |

2.5 |

3.6 |

6.8 |

10.8 |

14 |

20 |

26 |

|

|

Approximate power consumption (W) |

38 |

550 |

505 |

1260 |

1360 |

2370 |

2770 |

4247 |

4550 |

|

|

Air inlet and outlet caliber (BSP) |

1'' |

1'' |

1'' |

1½ |

2'' |

2½ |

3'' |

3'' |

3'' |

|

|

Conditions |

Inlet air temperature < 70 °C |

Ambient temperature < 45 degree °C |

C-air pressure 0.4-1.0 Mpa |

|||||||

|

Dew point temperature |

2-10 °C |

|||||||||

|

Types of refrigerants |

R-22 CR 134 Acceptable customization |

|||||||||

|

Medium type refrigerant compressor (HP) |

1/3 |

1/2 |

1/2 |

1 |

1½ |

2 |

3 |

5 |

5 |

|

|

Power Suppl |

AC 1 ph 220v/220v 50hz/60hz |

AC 3 ph 380v/400v 50hz/60hz |

||||||||

|

Outward Size |

Length |

700 |

750 |

750 |

930 |

1020 |

1150 |

1200 |

1350 |

1350 |

|

Width |

400 |

400 |

400 |

450 |

480 |

550 |

550 |

600 |

600 |

|

|

Height |

700 |

700 |

750 |

850 |

930 |

1030 |

1130 |

1350 |

1350 |

|