MOBO AIR COMPRESSOR DDV-TTV SERIES

MOBO multi-stage compressor

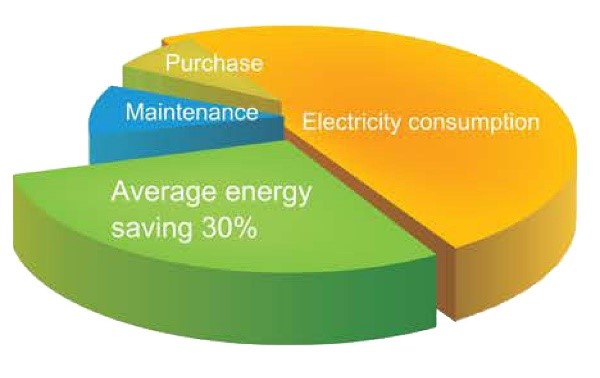

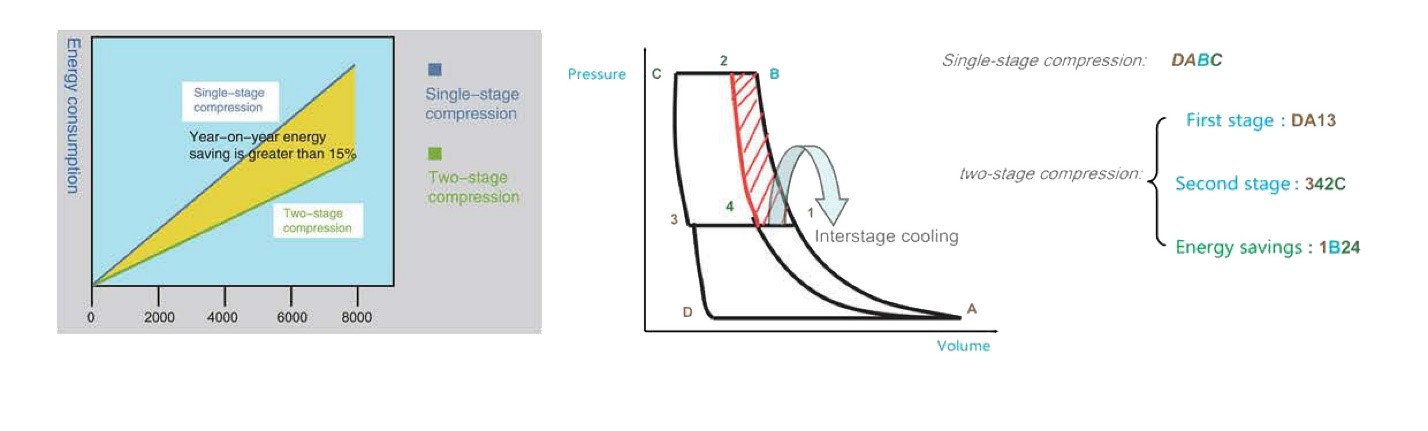

Efficient and reliable MOBO two-stage screw compressor is recognized by the world for its sophisticated and unique design, and fine manufacture. It has been tested by the global market for 40 years.

- The host rotor adopts high-efficiency GHH asymmetrical profile, which is easy to guarantee the machining accuracy and has high compression efficiency.

- The host exhaust end adopts a pair of taper roller bearings, which bear uniform load through wire contact, thus greatly prolonging the service life of the host.

- The coolant storage tank designed at the bearing of the host can avoid the dry friction at the starting moment, thus further prolonging the service life of the bearing.

- The shaft seal with oil return hole is designed at the shaft extension of the host to prevent the leakage of the lubricating oil.

|

|

|

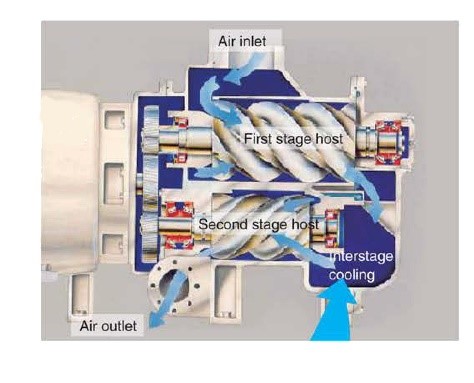

Interstage cooling of - The first stage host draws air from the atmosphere and compresses it to intermediate pressure - Air coming out of the first stage host enters the cooling curtain for cooling (interstage cooling) - The second stage host compresses the air to final exhaust pressure |

MOBO Air Compressor Power-energy machinery

MOBO Air Compressor Power-energy machinery

MOBO Control Panel

- Display with color screen;

- Digitization of information display:

- Human-computer Interaction is more friendly and keypad operation responds quickly:

- Display pressure, temperature, frequency, power, running time, etc;

- Constant temperature, constant pressure, timing and backdight setting:

- Support Modbus communication protocol:

- Automatic and freeze function,

MOBO PM Centrifugal Fan

- The fan has frequency conversion for energy saving Control so it realized stepless speed change, low noise;

- Largo alr volume, high pressure, high heat dissipation officiency:

- Low speed, long service life.

MOBO PM Motor

- Very high efficiency IPM motor E4, achieve protection grade IP65;

- Uso tho 0.35mm silloon stool shoot of Baostool of China;

- Magnetic steel is 380UH class, guaranteed no

- Demagnetization up to 180 degrees Excitation noise less than 65dB, dass B temperaturerise the power consumption on heating is less than 4%.

MOBO Smart Frequency Conversion Control System

- MOBO brand heavy-duty vector frequency conversion, widely adaptability, can work well in the environment of 48 degrees The key components are made by Siemens.

|

DDV 22 TTV160 (4-8bar) Technical parameters |

|||||||

|

Model |

Motor power (kW) |

Exhaust pressure (bar) |

Best FAD (m³/min) |

Reference FAD (m³/min) |

Dimensions (LxWxH)mm |

Outlet pipe diameter |

Unit weight (kg) |

|

DDV22-7 |

22 |

7(6-8) |

4.32 |

4.53 |

1300x980x1690 |

G1½ |

680 |

|

DDV37-7 |

37 |

7(6-8) |

7.15 |

7.5 |

1440x1150x1750 |

G2 |

850 |

|

TTV45-7 |

45 |

7(6-8) |

10.3 |

10.8 |

2300x1600x1600 |

DN80 |

2100 |

|

DDV55-7 |

55 |

7(6-8) |

12.8 |

14.2 |

2300x1350x1600 |

DN80 |

2000 |

|

TTV76-7 |

76 |

7(6-8) |

16.1 |

16.9 |

2600x1850x1800 |

DN80 |

2950 |

|

TTV90-7 |

90 |

7(6-8) |

19.3 |

20.2 |

2900x2050x2100 |

DN100 |

3150 |

|

DDV110-7 |

110 |

7(6-8) |

22.5 |

24.9 |

2950x2050x2120 |

DN100 |

3400 |

|

TTV132-7 |

132 |

7(6-8) |

27 |

28.3 |

2900x2050x2100 |

DN100 |

3750 |

|

TTV160-7 |

160 |

7(6-8) |

32.9 |

34.5 |

3450x2050x2100 |

DN100 |

4600 |

|

DDV30-5 |

30 |

5(4-6) |

7.35 |

7.71 |

1440x1150x1750 |

G2 |

850 |

|

TTV45-5 |

45 |

5(4-6) |

11.8 |

12.4 |

2300x1600x1600 |

DN80 |

2100 |

|

DDV55-4 |

55 |

5(4-6) |

15 |

16.6 |

2300x1350x1600 |

DN80 |

2050 |

|

TTV76-5 |

76 |

5(4-6) |

18.7 |

19.6 |

2600x1850x1800 |

DN80 |

2950 |

|

DDV90-5 |

90 |

5(4-6) |

24.3 |

25.3 |

2950x2050x2120 |

DN100 |

3400 |

|

TTV110-5 |

110 |

5(4-6) |

26.5 |

27.8 |

2900x2050x2100 |

DN100 |

3600 |

|

TTV115-5 |

115 |

5(4-6) |

27 |

28.3 |

3450x2050x2120 |

DN150 |

3750 |

|

TTV135-5 |

135 |

5(4-6) |

32.5 |

34.1 |

3450x2050x2120 |

DN150 |

4100 |

|

TTV160-5 |

160 |

5(4-6) |

40.6 |

42.6 |

3800x2050x2260 |

DN150 |

5800 |